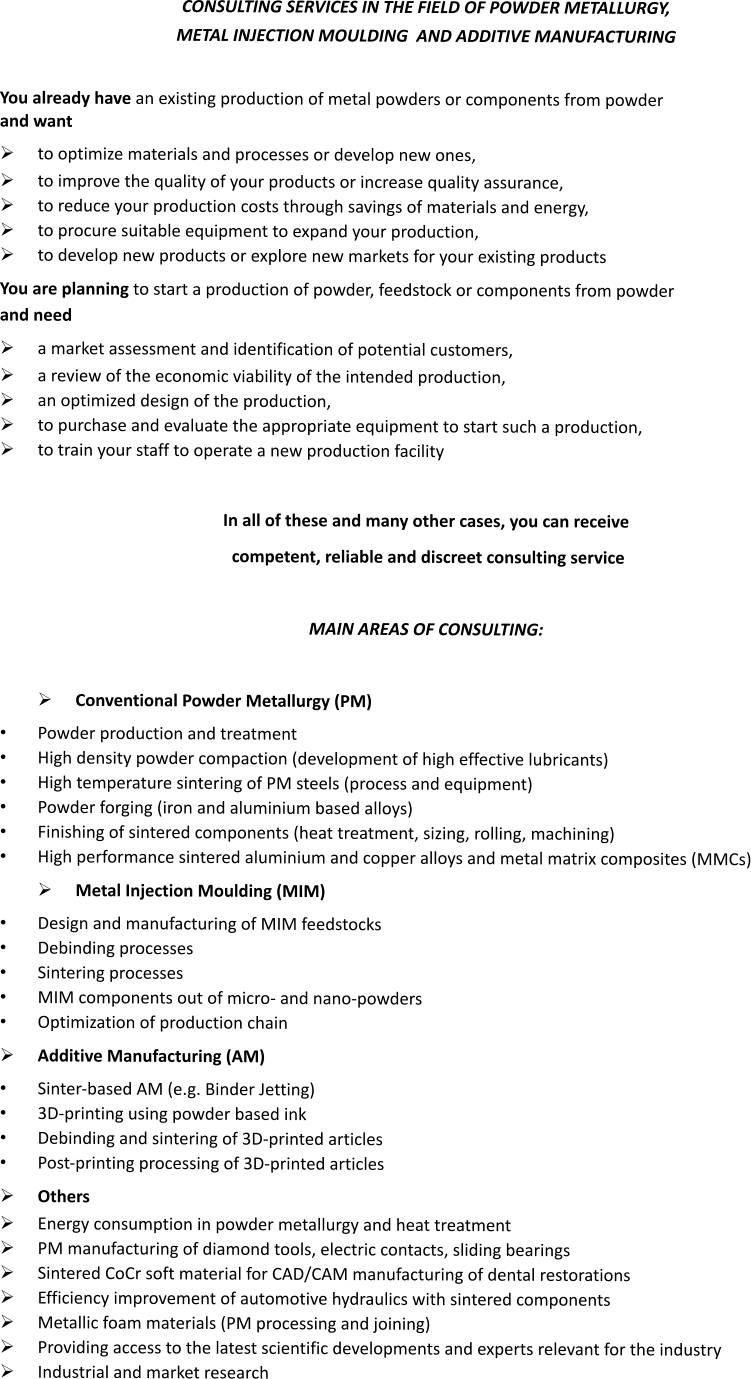

Powder Metallurgy, Metal Injection Moulding & Additive Manufacturing

Consulting

Dr. V. Kruzhanov

PM

Consulting Dr. V. Kruzhanov

PHONE: + 49 171 675 3041

Remscheid

CONTACT:

E-MAIL:

kruzhanov@pm-mim-consulting.com

Germany

WEB:

www@pm-mim-consulting.com